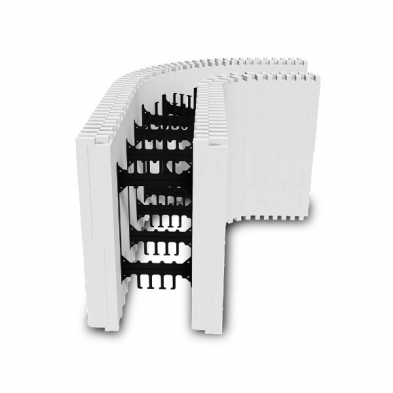

10″ 90º Bl KD Corner Block – 8/bundle

$425.00

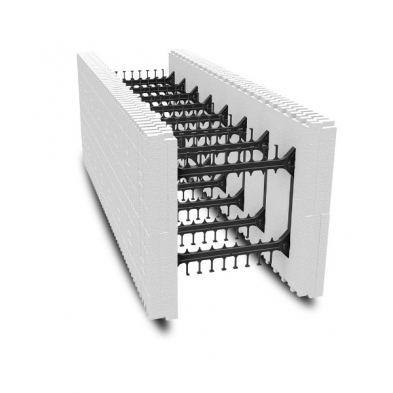

The BuildLock Knockdown ICF System is a high performance knock-down insulating concrete form (ICF) wall system comprised of two separate 2½ inch Expanded Polystyrene (EPS) panels which are connected by strong, high-density plastic webs on 6-inch centers. BuildLock is the strongest knock-down product on the market today.

Each web bridge features a 3-axis positive locking attachment that snaps the web securely in the proper position to eliminate racking and provide superior structural stability throughout the construction process. The BuildLock Knockdown block exceeds even the superior strength of BuildBlock ICF blocks.

Description

Why BuildLock Knockdown

- Available in 4”, 6”, 8”, 10”, 12” or greater core widths.

- BuildLock’s patented web is the strongest web on the market.

- Double-reinforced corner webs on 10” and 12” forms for safer pours and more attachment points.

- Expandable core for larger sizes (24”+) with optional bridge connectors.

- Blocks ship flat to reduce shipping costs and increase product storage capacity.

- Larger rebar saddles for multiple rebar sizes.

- Reinforced web flanges for additional strength.

- Simple, quick on-site assembly.

- Completely reversible webs for multiple rebar locations and 8” horizontal spacing.

- Connect multiple webs for special construction needs such as pilasters.

- Use BuildBlock Hardwall to create an ICF wall with bare concrete on one side.

Knockdown Advantages

- Commercial ICF block for projects requiring 4” to 12”+ concrete cores.

- Patented strongest ICF web design on 6” centers.

- Build 4”-24”+ walls using optional bridge clip connector.

- Integrate pilasters into ICF walls.

- Create insulated footings and foundations.

- Designed to easily allow 8” horizontal rebar spacing in large commercial projects.

- Tilt up & retrofit insulation applications.

- On-site assembly for integration of pre-set penetrations such as blast proof door and window frames.

BuildLock ICF Benefits

- Fully reversible blocks and webs.

- Numbered vertical cut lines every

- 1-inch and horizontal cut lines every 2-inches.

- Tight interlocking blocks with 100% surface-to-surface connections eliminating costly ties and accessories.

- High-Density Plastic Webs with 2 Extra Heavy Duty Attachment Points (450lb.+ pullout) on each web.

- Form and insulate in one step and use any finish application including BuildBlock Hardwall.

- 4-hour fire rating and low sound transmission.

- Fully integrates with all other BuildBlock ICF Products.

BL-1090 Specifications

| Specification | Imperial | Metric |

|---|---|---|

| Product ID | BL-1090 | BL-1290 |

| Length | 37” (ext) / 22” (int.) | 939mm (ext) / 558mm (int.) |

| Width | 15” (10” Core) | 381mm (254mm Core) |

| Height | 16” | 406mm |

| Return | 25” (ext) / 10” (int.) | 635mm (ext) / 254mm (int.) |

| Concrete Volume | 0.151444 yd3 | .115787 m3 |

| Surface Area | 6.88 sq.ft. | .6391 m2 |

| EPS Dimension | 2.5″ each panel | 63mm each panel |

| Quantity Per Bundle | 8 blocks/16 panels | 8 blocks/16 panels |

| EPS Foam Density (lbs./cu.ft.) | 1.5 lbs./cu.ft. | |

| EPS Foam Depth (in) | 2.5″ / 5″ Total | 6.35 cm / 12.7 cm Total |

Bundle Specifications

| Specification | Imperial | Metric |

|---|---|---|

| Bundle Dimensions | 40″ x 50.5″ x 49.5″ | 101.6 cm x 128.27 cm x 125.73 cm |

| Bundle Length | 40″ | 101.6 cm |

| Bundle Width | 50.5″ | 128.27 cm |

| Bundle Height | 49.5″ | 125.73 cm |

| Bundle Weight | 64lbs | 29 kg |

| Quantity Per Bundle | 8 blocks/16 panels | 8 blocks/16 panels |

Energy Efficiency Specifications

| Specification | |

|---|---|

| Actual R-Value | 4.4 Per inch of EPS Foam |

| Effective R-Value | R-24 to R-50 |

| K-Factor | .24 Per inch of EPS Foam |

| Steady State R-Value | R-21 Foam Value |

| U-Value | U-0.048 |

| Water Absorption | Less than 3% (ASTM C272) |

| Water Vapor | 0.56 perms per 2.5″ |

Safety Specifications

| Specification | |

|---|---|

| Concrete Compressive Strength (psi) | 3,000 |

| Concrete Pour Temperature Range | Down to 0°F (-18°C) |

| Firewall Rating | 5,000 to 12,000 lbs per lineal foot for 3 hours. |

| Sound Class 1-sided | STC Sound Class rating of 51 with 1/2-inch sheetrock on one side. |

| Sound Class 2-sided | STC Sound Class rating of 54 with 1/2-inch sheetrock on both sides. |

| SPECIFICATION | Imperial | Metric |

|---|---|---|

| Expanded Polystyrene density | 1.5 lbs./cu.ft. | 24.02769 kg/m3 |

| Average thickness of EPS | 2½” per panel (5” total) | 12.7cm (6.35cm per panel) |

| Material R-value | R-22 Foam Value | R-22 Foam Value |

| Performance R-value (concrete, form R-value, air infiltration reduction, and thermal mass) |

R-30 to R-52 | R-30 to R-52 U 0.33 to U 0.02 |

| Actual R-value per inch of EPS Foam | 4.2/inch | |

| Thermal Mass (form & concrete) | 4” Core: 47.5 lbs./ft2 6” Core: 72 lbs/ft2 8” Core: 96 lbs/ft2 10” Core: 119 lbs/ft2 12” Core: 143 lbs/ ft2 |

4” Core: 231.9 kg/m2 6” Core: 351.5 kg/m2 8” Core: 468.7 kg/m2 10” Core: 581.0 kg/m2 12” Core: 698.2 kg/m2 |

| K-Factor | .24/inch | |

| Water absorption | – 3% (ASMC272) | – 3% (ASMC272) |

| Water vapor | 0.56 perms per 2½” Panel | 0.84 metric perms per 2½” Panel |

| Sound class | 52 with ½” sheet rock on inside | 52 with ½” sheet rock on inside |

| Fire wall | 3 Hour Fire Rating on BB-600 Wall (Loading 5,000 lb. per lineal feet throughout test.) (Post test loading 12,000 lbs. per lineal foot with no additional depletion.) |

3 Hour Fire Rating on BB-600 Wall (Loading 7440.6 kg/m throughout test.) (Post test loading 17857.9 kg/m with no additional depletion.) |

| Concrete compressive strength | Recommended 3000 psi minimum | Recommended 20 MPa minimum |

| Recommended concrete pouring temperature* | 15°F to 120°F* | (-9°C to 49°C)* |

| *Properly handled, specially formulated concrete can be poured at temperatures as low as -15ºF (-26ºC). Consult your ready mix company. Important: At temperatures below freezing, you must cover all exposed concrete with insulating material. | ||

ASTM Standards Product Testing

BuildBlock ICFs are evaluated to ensure they meet or exceed a variety of industry standards tests. Visit http://buildblock.com/technical-support/product-testing/ for more information.

| Properties | ASTM TEST | RANGE REQUIRED | TEST VALUE |

|---|---|---|---|

| Density | ASTM D1622 | 1.5lb/ft³ | 1.69lb/ft² |

| Thermal Resistance | ASTM C177 | 4.0F.ft².h/Btu/in | 4.08F.ft².h/Btu/in |

| Compressive Strength | ASTM D1621 | 15.0 psi | 23.1 psi |

| Flexural Strength | ASTM C203 | 40.0 psi | 50.4 psi |

| Flame Spread | ASTM E84 | 25 Maximum | >25 |

| Smoke Developed | ASTM E84 | 450 Maximum | >450 |

| Fire Wall Rating | ASTM E119 | 3hr | |

| R-Value | ASTM C518 | R-22 | R-22 |

| STC Rating | ASTM E413 | STC 50 | STC 50 |

| Vapor Permanence | ASTM E96 | 3.5 perms/inch Maximum | 2.04 perms/inch |

Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation

| Specification Reference: ASTM C 578-92 | Type I | Type VIII | Type II | Type IX | |||

|---|---|---|---|---|---|---|---|

| Property | Units | ASTM Test | |||||

| Density, minimum | (pcf) | D 303 or D 1622 | 0.90 | 1.15 | 1.35 | 1.80 | |

| Density Ranger | (pcf) | C 177 or C 518 | 0.90-1.14 | 1.15-1.34 | 1.35-1.79 | 1.80-2.20 | |

| Thermal Conductivity K Factor |

at 25 F at 40 F at 75 F |

BTU/(hr.) (sq.ft.)(F/in.) |

0.23 0.24 0.26 |

.22 .235 .255 |

.21 .22 .24 |

.20 .21 .23 |

|

| Thermal Resistance | at 25 F at 40 F at 75 F |

at 1 inch thickness | 4.35 4.17 3.85 |

4.54 4.25 3.92 |

4.76 4.55 4.17 |

5.00 4.76 4.35 |

|

| Strength Properties Compressive 10% Deformation Flexural Tensile Shear Shear Modulus Modulus of Elasticity |

psi psi psi psi psi psi |

D 1621 C 203 D 1623 D 723 _____ _____ |

10-14 25-30 16-20 18-22 280-320 180-220 |

13-18 30-38 17-21 23-25 370-410 250-310 |

15-21 40-50 18-22 26-38 460-500 320-360 |

25-33 50-75 23-27 33-27 600-640 460-500 |

|

| Moisture Resistance WVT Absorption (vol.) Capillarity |

perm. in % –––– |

2.0-5.0 less than 4.0 none |

1.5-3.5 less than 3.0 none |

1.0-3.5 less than 3.0 none |

0.6-2.0 less than 3.0 none |

||

| Coefficient of Thermal Expansion | in./(in.)(F) | D696 | 0.000035 | 0.000035 | 0.000035 | 0.000035 | |

| Maximum Service Temperature Long-term Exposure Intermittent Exposure |

167 180 |

167 180 |

167 180 |

167 180 |

|||

| Oxygen Index | % | D 2863 | 24.0 | 24.0 | 24.0 | 24.0 | |

| Section | Content | Revised | Download |

|---|---|---|---|

| Section 1 | BuildBlock Installation & Technical Manual | 10/2015 | (8 MB) |

| BuildBlock Installation & Technical Manual (High Resolution) | 10/2015 | (71 MB) | |

| Section 2 | GlobalBlock Installation & Technical Manual | 9/2015 | (13 MB) |

| Section 3 | BuildDeck Roof & Floor Decking System Design, Engineering, and Installation Manual | 1/2011 | (5 MB) |

| Section 4 | BuildBlock Hardwall Installation Manual | 12/2015 | (11 MB) |

| Section 5 | ThermalSert & ThermalSert KD Manual | 7/2014 | (4 MB) |

| Section 6 | BuildBrace ICF Bracing & Alignment System Manual | 8/2015 | (7 MB) |

| Section 7 | BuildBuck ICF Window & Door Bucking Product & Installation Manual | 12/2015 | (7 MB) |

| Section 8 | BuildShield Termite & Firestop Protection Product & Installation Manual | 12/2015 | (4 MB) |

| Section 9 | BuildBlock ICF Products & Safe Room Engineering Manual | 4/2016 | (14 MB) |

| Section 10 | BuildBlock CAD Details | 10/2015 | (17 MB) |

| Section 11A | Prescriptive Method for Insulating Concrete Forms in Residential Construction, Second Edition | 1/2002 | (2 MB) |

| Section 11B | Prescriptive Method for Insulating Concrete Forms in Residential Construction, Second Edition Appendix | 1/2002 | (2 MB) |

| Section 12 | Prescriptive Method for Connecting Structural Insulated Panel Roofs to Concrete Wall Systems | 5/2008 | (519 kB) |

| Section 13 | BuildBlock 03 11 19 CSI Specifications | 10/2015 | (55 kB) (30 kB) (52 kB) (80 kB) |

| Section 14 | BuildBlock Code Approvals & Product Testing | 7/2015 | (5 MB) |

| Section 15 | White Papers and Industry Research (Click here to visit download page) New research and whitepapers are added to this section regularly. |

10/2015 | |

| These files create the most current version of the BuildBlock Technical & Installation Manual Binder. | |||

BuildBlock Installation & Howto Videos

Reviews

There are no reviews yet.