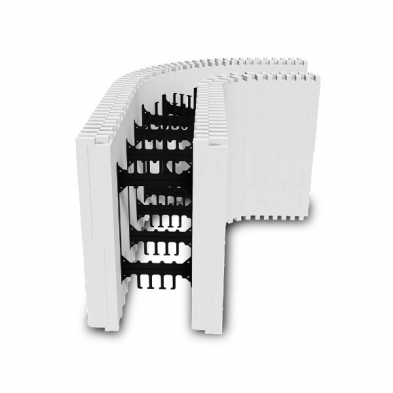

BuildRadius 6″ – 2′ Arc Qty Per Bundle: 12

$450.00

BuildRadius Wall & Pool ICF Radius Blocks

BuildRadius is a family of radius forms for use in ICF walls and pool construction. The BuildRadius forms create 2’, 4’, 8’, 12’, 16’, and 20’ arcs. Each of these blocks interlocks into any BuildBlock 6” product line and uses the standard BuildBlock web. Available in 6” widths initially, these forms are designed to ease construction of energy-efficient ICF pools, southwest style homes, bay windows, circular staircases, and provide options when designing unique areas in ICF homes.

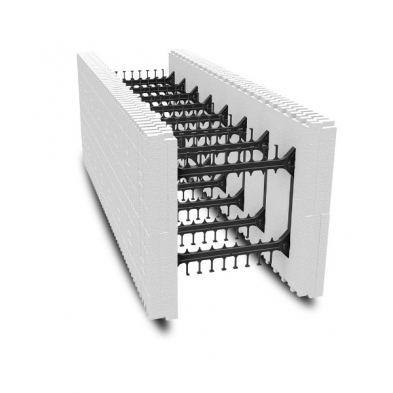

BuildBlock Insulating Concrete Forms (ICFs) are the most installer-friendly state-of-the-art 3rd generation insulating concrete form wall system. BuildBlock ICFs are designed to save you time, money, and hassle during installation. BuildBlock is designed to create the strongest structure, create less waste, install faster than other blocks on the market. BuildBlock ICFs are available in a variety of sizes with accessories for every application. Learn more about all our products at http://buildblock.com/products/

Description

BuildBlock ICF Benefits

- Ready to Stack. No on-site assembly required; start installing right off the truck.

- Fully Reversible. All forms are fully reversible; no top, bottom, left or right. Longer corner design provides automatic offset for each course.

- Industry Standard Size. Industry-standard 16-inch (406.4mm) high forms produce less waste when cutting around doors and windows.

- Tight Interlocking Blocks. Blocks easily stack and securely lock into place resulting in greater strength over the competition. No foam, clips, or ties required between courses.

- Foam Panels. Allows easy accommodation of electrical and plumbing installations.

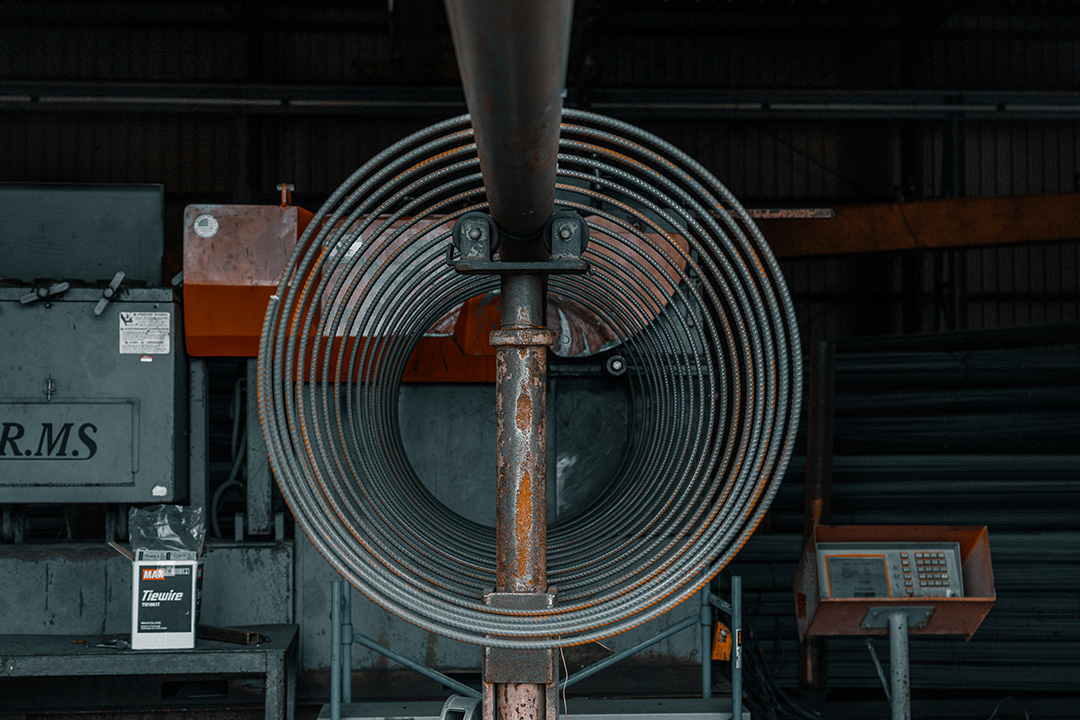

- Open Web Design. Interior rebar saddles provide rebar support without compromising concrete flow.

- 2.5-inch (63.5mm) Foam Panels. Allows easy accommodation of electrical and plumbing installation in the foam.

- Strongest interlocking connections for greater stability and precision alignment.

- Built-in 1-inch repeating interlock pattern reduces waste.

- Integrated numbered vertical cut lines & Molded horizontal cut lines.

- High-density plastic web molded into place every 6 inches on center for easier attachment of studs, cabinets, and other finishes.

- Patented and award winning technology.

- High-density Plastic Webs on 6-inch centers. Greater strength, more value.

- Deep Rebar Support locks in place and allows full contact laps and eliminates most steel tying.

- Easy mechanical chases for plumbing and electrical.

- Open Web Design for efficient concrete flow and half-height block support.

- Molded-in Tape Measure and Horizontal Cut Lines.

- 1-inch Repeating Cut Pattern on Block Connection.

- Lowest waste of any ICF on the market today.

- Attachment Point Markings

- No special half-height blocks required.

- Embedded 15″x1.5″ standard attachment points every 6-inches function as studs with 150lbs. pullout strength.

Key Advantages

- Molded-in “Tape Measure” and markings identify attachment points.

- Numbered, vertical cut lines every inch, often eliminate the need for using a tape measure.

- Extra Heavy-duty “BB” Attachment Points (450lbs.+) located every 8″ vertically and every 6″ horizontally, allowing for super secure attachment of bracing or heavy cabinetry.

- Attachment Point Markings

- Heavy-duty attachment points are marked with a BB. Molded-in Horizontal Cut Lines. Located every two inches; provide horizontal cutting references for straighter cuts.

BBR-602 Specifications

| Specification | Imperial | Metric |

|---|---|---|

| Product ID | BBR-602 | BBR-602 |

| 90° Arc Length | 2ft | 0.6069m |

| Block Angle | 90° | 90° |

| Outer Arc Length | 24in | 60.96cm |

| Inner Arc Length | 20.1875 in | 51.27625cm |

| Straight Section Length | 24in | 60.96cm |

| Panel Height | 16in | 40.64cm |

| Outer Panel Surface Area | 5.33ft² | 0.4951m² |

| Inner Panel Surface Area | 4.91ft² | 0.4561m² |

| Core Footprint | 164.16in² | 2690.10cm² |

| Concrete Volume | .056296yd³ | 0.043041m³ |

| Outer Diameter | 2.55ft | 0.77724m |

| Outer Diameter | 30.56in | 77.724cm |

| Outer Radius | 1.27ft | 8.2296cm |

| Outer Radius | 15.28in | 465.7344cm |

| Inner Diameter | .71ft | 21.64cm |

| Inner Radius | .36ft | 10.97cm |

| Circumference | 8.ft | 2.4384m |

| EPS Dimension | 2½” each panel | 63mm each panel |

| EPS Foam Density | 1.5 lbs./cu.ft. | 24.02769 kg/m3 |

| EPS Foam Depth | 2.5″ / 5″ Total | 6.35cm / 12.7cm Total |

Bundle Specifications

| Specification | Imperial | Metric |

|---|---|---|

| Bundle Dimensions | ||

| Bundle Length | ||

| Bundle Width | ||

| Bundle Height | ||

| Bundle Weight | ||

| Quantity Per Bundle |

Energy Efficiency Specifications

| Specification | |

|---|---|

| Actual R-Value | 4.4 Per inch of EPS Foam |

| Effective R-Value | R-24 to R-50 |

| K-Factor | .24 Per inch of EPS Foam |

| Steady State R-Value | R-21 Foam Value |

| U-Value | U-0.048 |

| Water Absorption | Less than 3% (ASTM C272) |

| Water Vapor | 0.56 perms per 2.5″ |

Safety Specifications

| Specification | |

|---|---|

| Concrete Compressive Strength (psi) | 3,000 |

| Concrete Pour Temperature Range | Down to 0°F (-18°C) |

| Firewall Rating | 5,000 to 12,000 lbs per lineal foot for 3 hours. |

| Sound Class 1-sided | STC Sound Class rating of 51 with 1/2-inch sheetrock on one side. |

| Sound Class 2-sided | STC Sound Class rating of 54 with 1/2-inch sheetrock on both sides. |

General Specifications

| SPECIFICATION | Imperial | Metric |

|---|---|---|

| Expanded Polystyrene density | 1.5 lbs./cu.ft. | 24.02769 kg/m3 |

| Average thickness of EPS | 2½” per panel (5” total) | 12.7cm (6.35cm per panel) |

| Material R-value | R-22 Foam Value | R-22 Foam Value |

| Performance R-value (concrete, form R-value, air infiltration reduction, and thermal mass) |

R-30 to R-52 | R-30 to R-52 U 0.33 to U 0.02 |

| Actual R-value per inch of EPS Foam | 4.2/inch | |

| Thermal Mass (form & concrete) | 4” Core: 47.5 lbs./ft2 6” Core: 72 lbs/ft2 8” Core: 96 lbs/ft2 10” Core: 119 lbs/ft2 12” Core: 143 lbs/ ft2 |

4” Core: 231.9 kg/m2 6” Core: 351.5 kg/m2 8” Core: 468.7 kg/m2 10” Core: 581.0 kg/m2 12” Core: 698.2 kg/m2 |

| K-Factor | .24/inch | |

| Water absorption | – 3% (ASMC272) | – 3% (ASMC272) |

| Water vapor | 0.56 perms per 2½” Panel | 0.84 metric perms per 2½” Panel |

| Sound class | 52 with ½” sheet rock on inside | 52 with ½” sheet rock on inside |

| Fire wall | 3 Hour Fire Rating on BB-600 Wall (Loading 5,000 lb. per lineal feet throughout test.) (Post test loading 12,000 lbs. per lineal foot with no additional depletion.) |

3 Hour Fire Rating on BB-600 Wall (Loading 7440.6 kg/m throughout test.) (Post test loading 17857.9 kg/m with no additional depletion.) |

| Concrete compressive strength | Recommended 3000 psi minimum | Recommended 20 MPa minimum |

| Recommended concrete pouring temperature* | 15°F to 120°F* | (-9°C to 49°C)* |

| *Properly handled, specially formulated concrete can be poured at temperatures as low as -15ºF (-26ºC). Consult your ready mix company. Important: At temperatures below freezing, you must cover all exposed concrete with insulating material. | ||

ASTM Standards Product Testing

BuildBlock ICFs are evaluated to ensure they meet or exceed a variety of industry standards tests. Visit http://buildblock.com/technical-support/product-testing/ for more information.

| Properties | ASTM TEST | RANGE REQUIRED | TEST VALUE |

|---|---|---|---|

| Density | ASTM D1622 | 1.5lb/ft³ | 1.69lb/ft² |

| Thermal Resistance | ASTM C177 | 4.0F.ft².h/Btu/in | 4.08F.ft².h/Btu/in |

| Compressive Strength | ASTM D1621 | 15.0 psi | 23.1 psi |

| Flexural Strength | ASTM C203 | 40.0 psi | 50.4 psi |

| Flame Spread | ASTM E84 | 25 Maximum | >25 |

| Smoke Developed | ASTM E84 | 450 Maximum | >450 |

| Fire Wall Rating | ASTM E119 | 3hr | |

| R-Value | ASTM C518 | R-22 | R-22 |

| STC Rating | ASTM E413 | STC 50 | STC 50 |

| Vapor Permanence | ASTM E96 | 3.5 perms/inch Maximum | 2.04 perms/inch |

Standard Specification for Rigid, Cellular Polystyrene Thermal Insulation

| Specification Reference: ASTM C 578-92 | Type I | Type VIII | Type II | Type IX | |||

|---|---|---|---|---|---|---|---|

| Property | Units | ASTM Test | |||||

| Density, minimum | (pcf) | D 303 or D 1622 | 0.90 | 1.15 | 1.35 | 1.80 | |

| Density Ranger | (pcf) | C 177 or C 518 | 0.90-1.14 | 1.15-1.34 | 1.35-1.79 | 1.80-2.20 | |

| Thermal Conductivity K Factor |

at 25 F at 40 F at 75 F |

BTU/(hr.) (sq.ft.)(F/in.) |

0.23 0.24 0.26 |

.22 .235 .255 |

.21 .22 .24 |

.20 .21 .23 |

|

| Thermal Resistance | at 25 F at 40 F at 75 F |

at 1 inch thickness | 4.35 4.17 3.85 |

4.54 4.25 3.92 |

4.76 4.55 4.17 |

5.00 4.76 4.35 |

|

| Strength Properties Compressive 10% Deformation Flexural Tensile Shear Shear Modulus Modulus of Elasticity |

psi psi psi psi psi psi |

D 1621 C 203 D 1623 D 723 _____ _____ |

10-14 25-30 16-20 18-22 280-320 180-220 |

13-18 30-38 17-21 23-25 370-410 250-310 |

15-21 40-50 18-22 26-38 460-500 320-360 |

25-33 50-75 23-27 33-27 600-640 460-500 |

|

| Moisture Resistance WVT Absorption (vol.) Capillarity |

perm. in % –––– |

2.0-5.0 less than 4.0 none |

1.5-3.5 less than 3.0 none |

1.0-3.5 less than 3.0 none |

0.6-2.0 less than 3.0 none |

||

| Coefficient of Thermal Expansion | in./(in.)(F) | D696 | 0.000035 | 0.000035 | 0.000035 | 0.000035 | |

| Maximum Service Temperature Long-term Exposure Intermittent Exposure |

167 180 |

167 180 |

167 180 |

167 180 |

|||

| Oxygen Index | % | D 2863 | 24.0 | 24.0 | 24.0 | 24.0 | |

Please use the BuildBlock ICF installation resources mentioned below to build the safest and most successful ICF projects possible. More information can be found on our mail website at http://buildblock.com. Please also visit our Youtube Channel at https://www.youtube.com/user/BuildBlock for product videos, installation videos, project tours, howto videos and more.

Installation Brochures & Quick Start Guides

BuildBlock Product Installation Manuals

The table below provides a link to the BuildBlock Product Installation Manual. The manual is freely downloadable and a hard copy is available for purchase here in the store. Please read this manual to fully understand how to properly install BuildBlock ICFs. If you have any questions, more information can be found on our website at http://buildblock.com/technical-support or by contacting your sales representative or our technical department at 866-222-2575. Our goal is for you to build successful ICF projects that will last for generations. Our motto is Build it once, Build it for life.

| Section | Content | Revised | Download |

|---|---|---|---|

| Section 1 | BuildBlock Installation & Technical Manual | 10/2015 | (8 MB) |

| BuildBlock Installation & Technical Manual (High Resolution) | 10/2015 | (71 MB) | |

| Section 2 | GlobalBlock Installation & Technical Manual | 9/2015 | (13 MB) |

| Section 3 | BuildDeck Roof & Floor Decking System Design, Engineering, and Installation Manual | 1/2011 | (5 MB) |

| Section 4 | BuildBlock Hardwall Installation Manual | 12/2015 | (11 MB) |

| Section 5 | ThermalSert & ThermalSert KD Manual | 7/2014 | (4 MB) |

| Section 6 | BuildBrace ICF Bracing & Alignment System Manual | 8/2015 | (7 MB) |

| Section 7 | BuildBuck ICF Window & Door Bucking Product & Installation Manual | 12/2015 | (7 MB) |

| Section 8 | BuildShield Termite & Firestop Protection Product & Installation Manual | 12/2015 | (4 MB) |

| Section 9 | BuildBlock ICF Products & Safe Room Engineering Manual | 4/2016 | (14 MB) |

| Section 10 | BuildBlock CAD Details | 10/2015 | (17 MB) |

| Section 11A | Prescriptive Method for Insulating Concrete Forms in Residential Construction, Second Edition | 1/2002 | (2 MB) |

| Section 11B | Prescriptive Method for Insulating Concrete Forms in Residential Construction, Second Edition Appendix | 1/2002 | (2 MB) |

| Section 12 | Prescriptive Method for Connecting Structural Insulated Panel Roofs to Concrete Wall Systems | 5/2008 | (519 kB) |

| Section 13 | BuildBlock 03 11 19 CSI Specifications | 10/2015 | (55 kB) (30 kB) (52 kB) (80 kB) |

| Section 14 | BuildBlock Code Approvals & Product Testing | 7/2015 | (5 MB) |

| Section 15 | White Papers and Industry Research (Click here to visit download page) New research and whitepapers are added to this section regularly. |

10/2015 | |

| These files create the most current version of the BuildBlock Technical & Installation Manual Binder. | |||

Reviews

There are no reviews yet.